NEW - 40 GALLON DOUBLE PLANETARY MIXER - S/S - VACUUM - JACKETED

or

Call 216-409-1394

Description

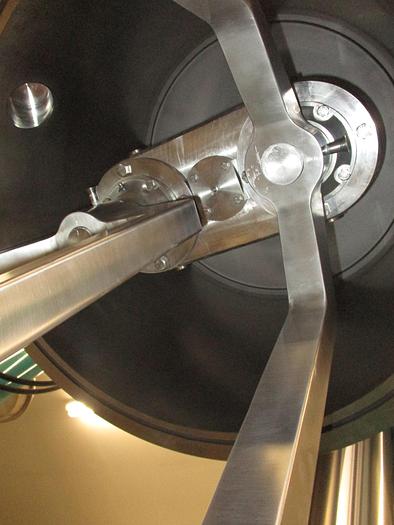

NEW Heavy Duty Machine, Inc. Model HDM-DP-40 Double Planetary Mixer with a working capacity of 40 gallons (full holding capacity of 47 gallons), including the following features and specifications:

15 HP/XP inverter duty motor.

304 stainless steel gearbox housing.

304 stainless steel stirrer shafts & rectangular blades

Vacuum Top Cover

304 stainless steel jacketed mix can

*16-18 Week Lead Time (Subject To Supply Chain)

Terms: 50% With Order, Balance Upon Completion Of Construction,

Prior To Shipment

We Also Offer NEW Discharge Ram Systems

Specifications

| Manufacturer | Heavy Duty Machine, Inc. |

| Model | HDM-DP-40 |

| Condition | New |

| Stock Number | 10771 |

| Size (smallest to largest) | 40.0 Gallon |